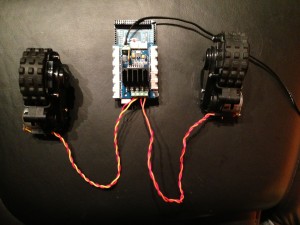

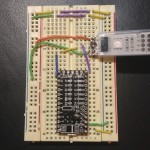

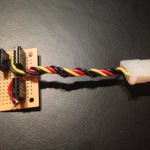

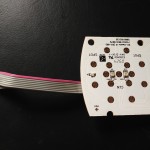

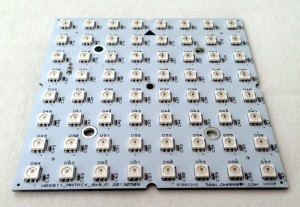

I helped fund a kickstarter project a few months back and I just received my 8×8 RGB123 LED Matrix reward for my pledge: It is a 64 (8X8) RGB123 Led matrix based on the latest WS2812B LEDs with two XT60 high current M/F connectors, two 3 pin headers, and a servo wire. For a $30 dollar pledge I am super happy with it and the overall Kickstarter experience.

It is a 64 (8X8) RGB123 Led matrix based on the latest WS2812B LEDs with two XT60 high current M/F connectors, two 3 pin headers, and a servo wire. For a $30 dollar pledge I am super happy with it and the overall Kickstarter experience.

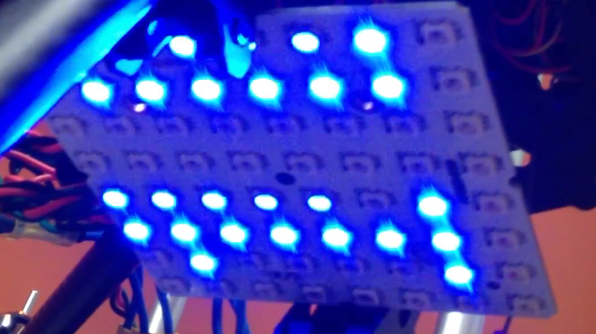

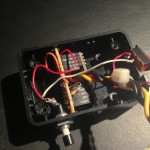

Here is a little demo of the RGB123 LED Matrix

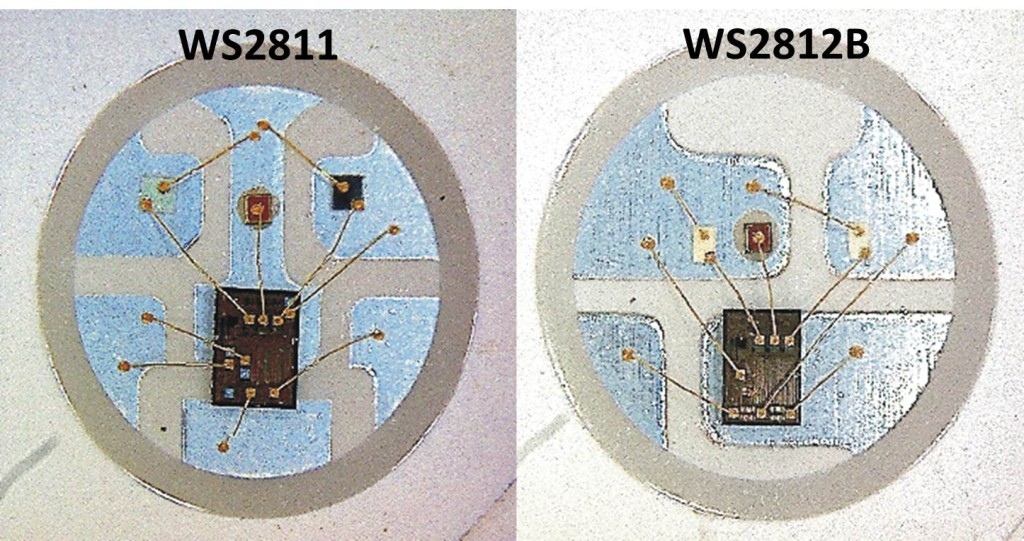

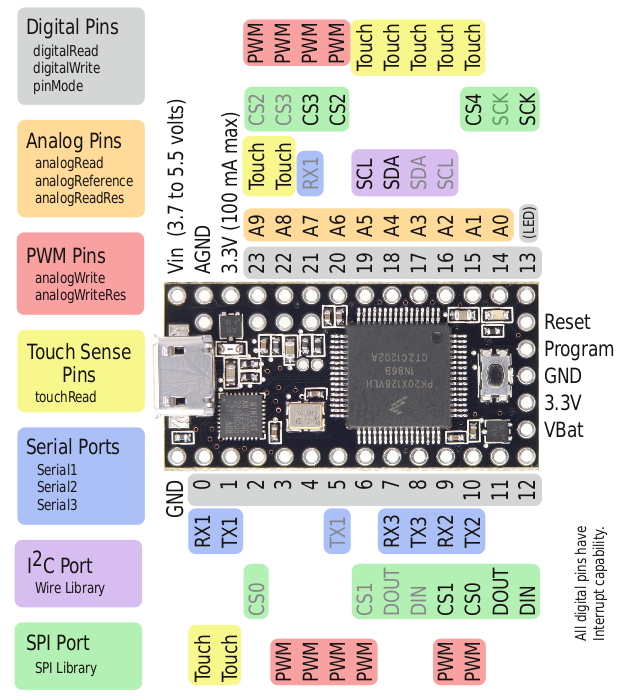

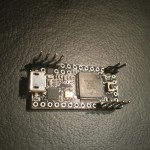

I have experience with the WS2801 chip from my IALED Pants project and it amazes me that only a few years later the led has the addressing ic embedded right in to it. The main differences for me for using the WS2812 over WS2801 is the WS2812 only needs one data line and can work at 8 or 16 megahertz. The WS2812 does not use the SPI protocol like the ws2801 therefore it does not need a clock line.

WS2812 LED modules run at 800khz, not the typical 400khz protocol available on ws2811 modules. This equates to twice the speed, allowing programs to communicate with WS2812 much faster. WS2811 and WS2812 require each color to be pre computed. The program can’t compute the 1st, color send it and then move to the next color. Instead, each color needs to be computed, buffered and send when all colors are computed. This can lead to a limitation depending on the controller being used. Depending on the library being used, each led typically takes up 4 bytes of EEPROM.

| Board | EEPROM Bytes | Number of LEDs |

| Teensy 2.0 | 1024 | 256 |

| Teensy++ 2.0 | 4096 | 1024 |

| Teensy 3.0 | 2048 | 512 |

| Teensy 3.1 | 2048 | 512 |

| Digispark | 512 | 10 |

| DigiX | 4096 | 1024 |

| Teensy 2.0 | 1024 | 256 |

| Teensy ++ 2.0 | 4096 | 1024 |

| Teensy 3.0 | 2048 | 512 |

| Teensy 3.1 | 2048 | 512 |

| Uno | 1024 | 256 |

| Due | 524 | 131 |

| Leonardo | 1024 | 256 |

| Mega 2560 | 4096 | 1024 |

| Mega ADK | 4096 | 1024 |

| Micro | 1024 | 256 |

| Mini | 1024 | 256 |

| Nano ATmega168 | 524 | 131 |

| Nano ATmega328 | 1024 | 256 |

| Ethernet | 1024 | 256 |

| Esplora | 1024 | 256 |

| ArduinoBT | 1024 | 256 |

| Fio | 1024 | 256 |

| Pro ATmega168 | 524 | 131 |

| Pro ATmega328 | 1024 | 256 |

| Pro Mini | 524 | 131 |

| LilyPad | 524 | 131 |

| LilyPad USB | 1024 | 256 |

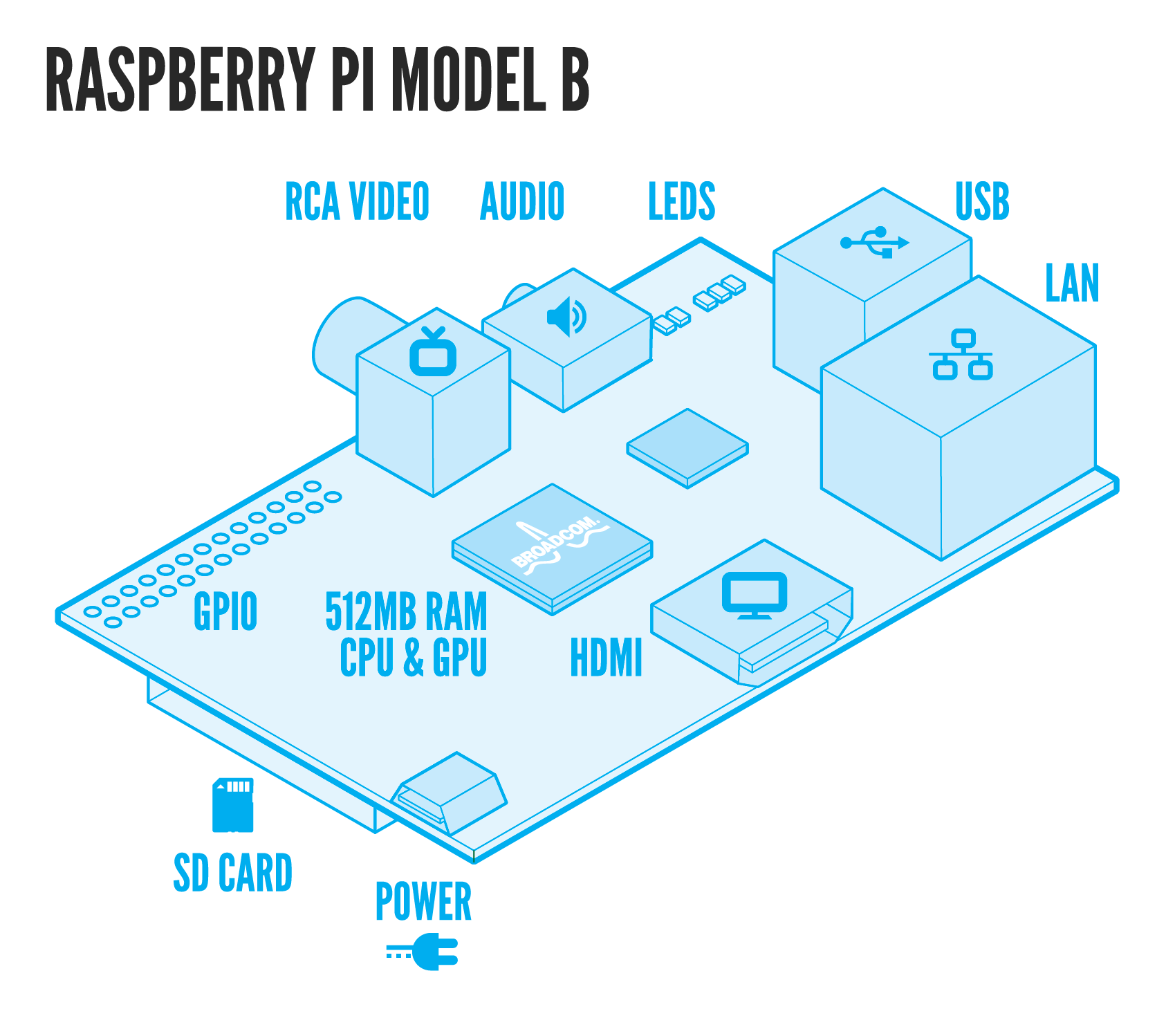

This isn’t as big of a limitation as one would think because you always have the ability to run multiple strips in parallel. The limit of strips is limited by the number of available pins. I recommend using ws2812 or ws2811 for all projects going forward unless you plan to use the SPI port. For instance if you wish to use a Raspberry Pi as a controller I recommend using WS2801 LEDs.

Over all I am very happy with the quality of the RGB123 LED Matrix and I hope to order a few more in the coming months. I really want to order on 16×16 matrix.